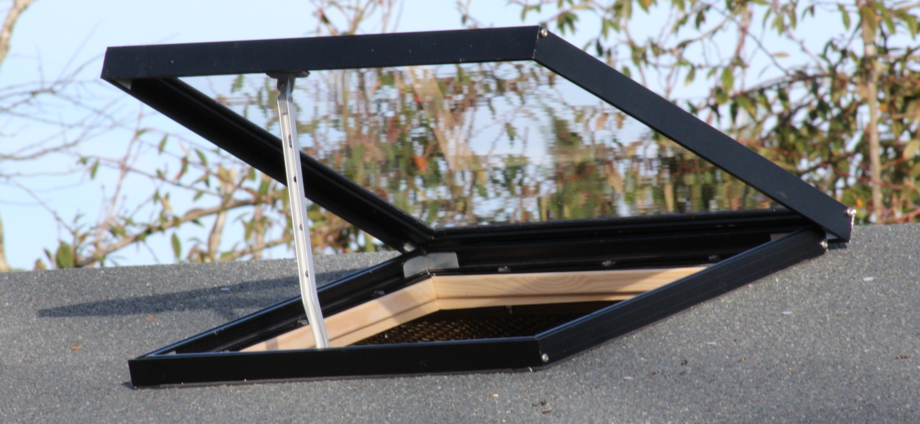

NATURAL LIGHT, VENTILATION and SECURITY SOLUTIONS for GARDEN BUILDINGS

Accessories to fit all New and Existing Timber Buildings, including Sheds, Summerhouses, Log Cabins, Work shops, Potting Sheds, Man Caves, She Caves, Gyms, Hobby Rooms, Play Rooms, Home Offices, Store Rooms, Pub Sheds, Garden Rooms, and so much more!

Installation Guides

Watch the Installation video to see just how simple Installation can be.

Activent K Series Windows and Skylights are designed to be installed from inside the building, under no circumstances is it nessacerry to climb upon the roof!

Quick Specifications:

Max External size 500mm x 500mm (Lid)

Less than 40mm Tall

4mm Tough Acrylic Glazing, 4mm Single Glass Or

18mm Double Glazed Glass

Internal hole to cut 400mm wide x 385 depth

Minimum Distance required between purlins (internal) 465mm wide x 450mm deep

All Windows and Sylights are identical in size and fitting

Download the full fitting instructions for your Opening Roof Window

Fitting Your Roof Window Standard.pdf

Adobe Acrobat document [799.8 KB]

Download the full fitting instructions for your Fixed Double Glazed Skylight

Fitting Your Glass Skylight.pdf

Adobe Acrobat document [634.9 KB]

Download the full fitting instructions for your Onduline & Coroline Roof Window & Skylight

Onduline Roof Window Fiitng Instructions[...]

Adobe Acrobat document [1.9 MB]

Full Written Instructions are included in the Kit, If you have any questions or are unsure at any time please feel free to contact us.

You could also employ a Handyman to install your window and many tradesmen websites are available.

7) Working through the hole from the inside, align the base unit from above with the timber collar. Drill through the pre-drilled holes in the base unit through the roof and colllar using a 6mm drill bit (it is best to “G” clamp this in position). After drilling all of the holes (twelve off), remove the clamps and bring the base unit back into the building. TIP: Use 7mm to widen and give clearance for the bolts through the wood only

8) Re-assemble the lid to the base unit and remove the protective tape from the foam sealing gasket arround the base. Clean any loose material from the felt and base unit and pass the re-assembled vent through the opening and place in position. (On steep pitched roofs secure with ‘G’ clamps.)

Open the roof vent (securing with the stay to allow unobstructed access) slide all washers back into place before inserting the 6mm stainless steel bolts through the frame, roof and timber collar.

9) Fit washers and nuts from the underside and lightly tighten. Working clockwise and starting from the centre of the top, begin to tighten the nuts. (It is best to go around several times to ensure an even compression of the sealing foam).

When correct compression is achieved, a deviation will be noticed in the base unit and around the bolt heads/washers in the timber collar, this is to be expected and has been designed to give the correct compression.

For more fitting instructions check out the other pages "Felt shingles" "Insulated or Clad Roofs"

TOOLS REQUIRED;

-

6mm, 7mm & 8mm drill bits

-

Electric/battery drill

-

Electric/battery jigsaw

-

8mm spanner

-

2 x 10mm spanner

-

“G” Clamps

CLEANING:

-

The roof vent should only be washed using a sponge with plenty of clean water to avoid scratching.

-

Caustic detergents and solvents may damage the acrylic and your felt roof.

DO NOT LEAVE ROOF VENT OPEN IN HIGH WINDS

Citrus Sales

Unit 16, Hanger 3

Rudford Industrial Estate

Ford Road

Ford

West Sussex

BN18 0BD

01903 442 155

info@activent.co.uk

info@citrussales.co.uk